ITEM SPECIFICS

-

Brand

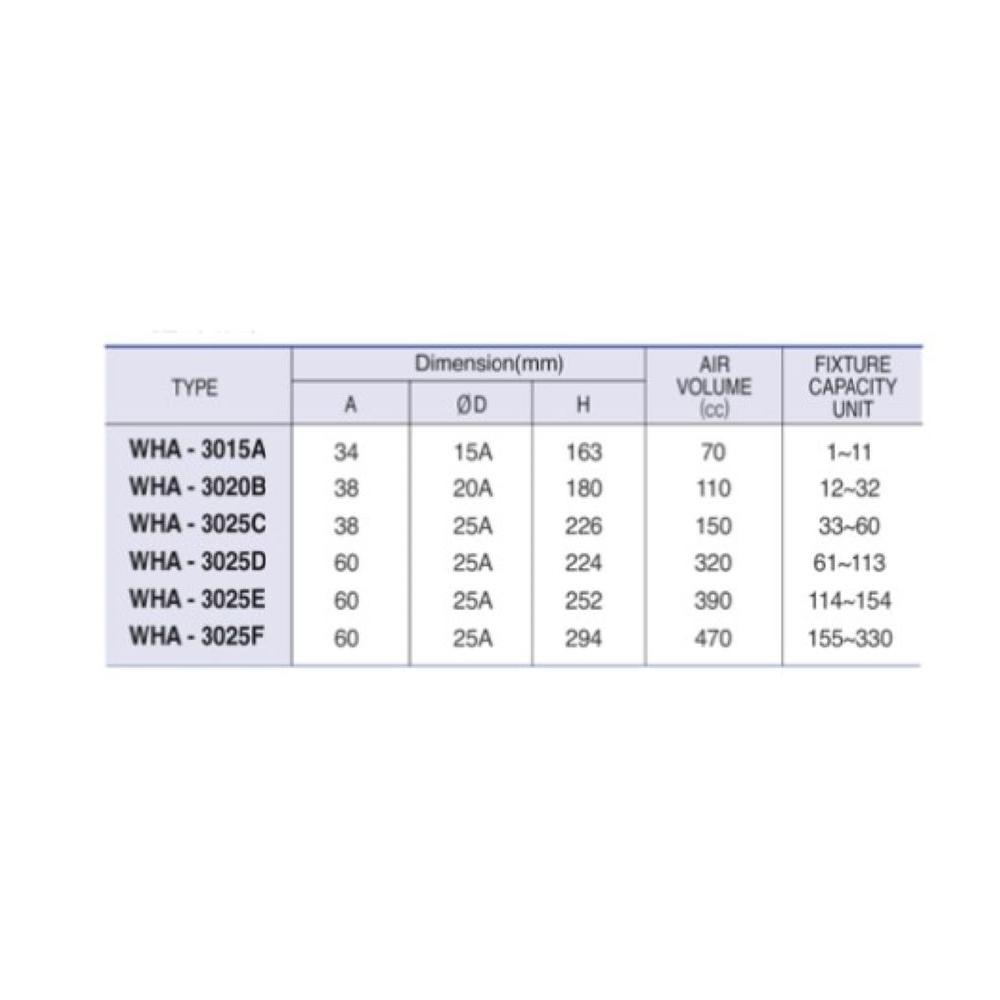

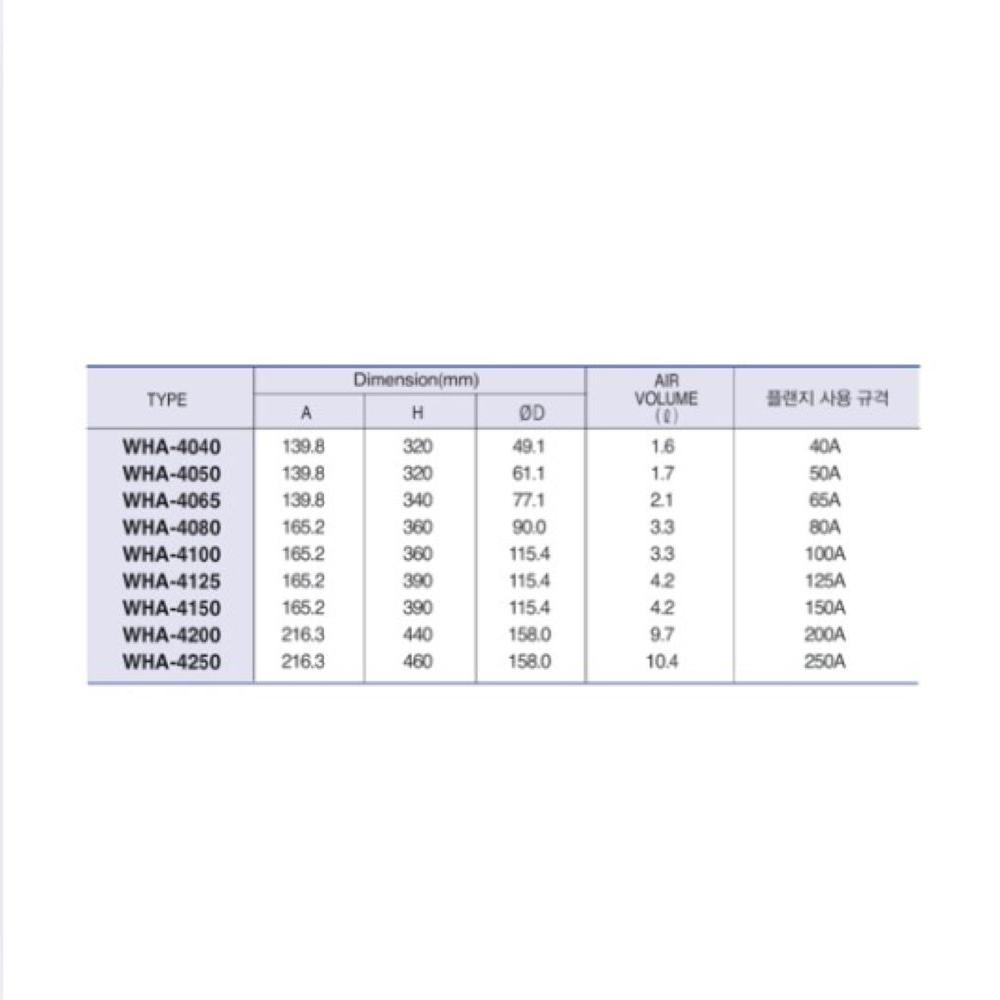

Model WHAWater hammer arrester

-

origin

Republic of Korea

-

Size(Capacity)

N/A

PRODUCT DESCRIPTION

SUS Water Hammer Arrester (adapter, flange)

The SUS Water Hammer Arrester is a device specifically designed to absorb and mitigate water hammer (hydraulic shock) in piping systems caused by sudden valve closure, pump start/stop, or rapid changes in flow velocity. Unlike conventional models, this arrester is manufactured entirely from stainless steel (SUS), ensuring superior corrosion resistance, durability, and hygienic performance for long-term use in demanding environments.

The SUS Water Hammer Arrester is a device specifically designed to absorb and mitigate water hammer (hydraulic shock) in piping systems caused by sudden valve closure, pump start/stop, or rapid changes in flow velocity. Unlike conventional models, this arrester is manufactured entirely from stainless steel (SUS), ensuring superior corrosion resistance, durability, and hygienic performance for long-term use in demanding environments.

1. Key Features

Full Stainless Steel Construction (SUS304 / SUS316 optional)

Provides exceptional resistance against corrosion, oxidation, and chemical attack, making it ideal for aggressive or sanitary environments.

Hydraulic Shock Absorption

Internal diaphragm or piston mechanism absorbs sudden pressure surges, protecting pipes, pumps, and valves.

Extended Service Life

Stainless steel housing ensures long-term durability and minimizes maintenance requirements compared to carbon steel alternatives.

Hygienic and Clean Design

Smooth internal surface prevents scale buildup, suitable for potable water, food & beverage, and pharmaceutical applications.

Compact Installation

Space-saving design allows installation in confined piping layouts without compromising performance.

Full Stainless Steel Construction (SUS304 / SUS316 optional)

Provides exceptional resistance against corrosion, oxidation, and chemical attack, making it ideal for aggressive or sanitary environments.

Hydraulic Shock Absorption

Internal diaphragm or piston mechanism absorbs sudden pressure surges, protecting pipes, pumps, and valves.

Extended Service Life

Stainless steel housing ensures long-term durability and minimizes maintenance requirements compared to carbon steel alternatives.

Hygienic and Clean Design

Smooth internal surface prevents scale buildup, suitable for potable water, food & beverage, and pharmaceutical applications.

Compact Installation

Space-saving design allows installation in confined piping layouts without compromising performance.

2. Technical Advantages of SUS Material

Corrosion Resistance: Maintains integrity even in high-moisture, saline, or chemically aggressive environments.

Structural Strength: Withstands repeated pressure surges without material fatigue.

Sanitary Properties: Complies with hygiene requirements for clean water, process water, and industrial liquids.

Versatility: Applicable across HVAC, industrial, and specialized piping systems requiring enhanced protection.

Corrosion Resistance: Maintains integrity even in high-moisture, saline, or chemically aggressive environments.

Structural Strength: Withstands repeated pressure surges without material fatigue.

Sanitary Properties: Complies with hygiene requirements for clean water, process water, and industrial liquids.

Versatility: Applicable across HVAC, industrial, and specialized piping systems requiring enhanced protection.

3. Applications

Building Services: Cold and hot water supply, fire-fighting piping systems

Industrial Plants: Chemical, pharmaceutical, and food & beverage process lines

HVAC Systems: Chilled water and condenser water piping

Special Facilities: Semiconductor plants, clean rooms, and environments where contamination prevention is critical

Building Services: Cold and hot water supply, fire-fighting piping systems

Industrial Plants: Chemical, pharmaceutical, and food & beverage process lines

HVAC Systems: Chilled water and condenser water piping

Special Facilities: Semiconductor plants, clean rooms, and environments where contamination prevention is critical

4. Performance & Benefits

Prevents damage to piping systems caused by hydraulic shock

Reduces noise generated by sudden water hammer events

Enhances operational safety and reliability of pumps, valves, and fittings

Provides long-term, maintenance-friendly performance through SUS construction

Prevents damage to piping systems caused by hydraulic shock

Reduces noise generated by sudden water hammer events

Enhances operational safety and reliability of pumps, valves, and fittings

Provides long-term, maintenance-friendly performance through SUS construction

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Telegraphic Transfer : T/T

- Name : YOON EUN JOONG

SHIPPING

Shipping from :

Republic of Korea

- 547 Aenggogae-ro, Namdong-gu, Incheon (21691)

NSV Co., Ltd.

The person in charge

Eun Joong YOONAddress

547 Aenggogae-ro, Namdong-gu, Incheon (21691)

Introduction

Leading the Future of Noise and Vibration Control with 40 Years of Expertise

NSV Co., Ltd. is a leading Korean company that has built unique expertise in noise, vibration, and shock control since its establishment in 1986. With 40 years of experience and continuous innovation, we have become a trusted partner in over 20 countries, providing the best solutions for various projects in construction, infrastructure, and industry

Our Key Strengths

Global Trust and Proven Technology: We earn over 3 million USD in exports annually and have gained global recognition for our technology and quality with international certifications like UL, FM, CE, and ISO. We have also received multiple awards from the Korean government for our export and product quality, proving our global competitiveness.

Complete and Efficient Solutions: We go beyond just selling products. We offer total solutions that include analysis, design, and consulting. By accurately studying a project's needs, we provide customers with the most effective and cost-efficient custom solutions.

Technology for a Safe and Green Environment: We use essential seismic and eco-friendly products to help Vietnam's fast-growing cities, industrial complexes, and factories develop sustainably. In particular, our hybrid dampers and structural damping devices, which protect against external shocks like earthquakes, play a key role in building a safe urban infrastructure.

Main Products and Services

NSV provides a wide range of solutions for noise, vibration, and shock control.

Vibration and Noise Control: Anti-vibration springs, rubber pads, soundproofing materials, etc.

Water Hammer Arresters: These devices absorb the sudden pressure changes in pipes (water hammer) to protect industrial piping systems.

Seismic Solutions: We offer hybrid dampers, PO-MAT, and structural damping devices used in tall buildings, bridges, and civil infrastructure.

Technical Consulting and Analysis Services: We provide detailed analysis and technical advice on noise, vibration, and earthquakes using professional software like Simcenter 3D, SOUND PLAN, and NX NASTRAN.

-

- Business Type :

- Manufacturer

-

- Main Product :

- Noise, vibration, and shock control equipment

-

- Established :

- 1992-07-01

-

- Total Annual Revenue :

- More than 10 billion (KRW)

-

- Total Employees :

- 51~100 people

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- More than 10 billion (KRW)

-

- Total export revenue (previous year in USD)

- 1,073

-

- Number of foreign trade employees

- 51~100 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

GOLD

GOLD

- NSV Co., Ltd. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★